Get a Grip on Savings! 20% OFF Toolit Grippers – Limited Time Only!

- CONFIGURATOR

No configuration exists for these dimensions. Please try adjusting the object length, object width or edge distance inputs.

SPECIFICATIONS ˄

Configuration:

Product number: 220 000 71-06

Weight:

Price:

€0,-

Datasheet

Manual

3D model

PERFORMANCE BETA ˄

The combined weight of the object and the tool exceed the lifting capacity of the robot. Therefore no performance data can be provided.

Default values have been used to calculate the performance scores because the form was not fully completed:

STABILITY SCORE

GRIP STRENGTH

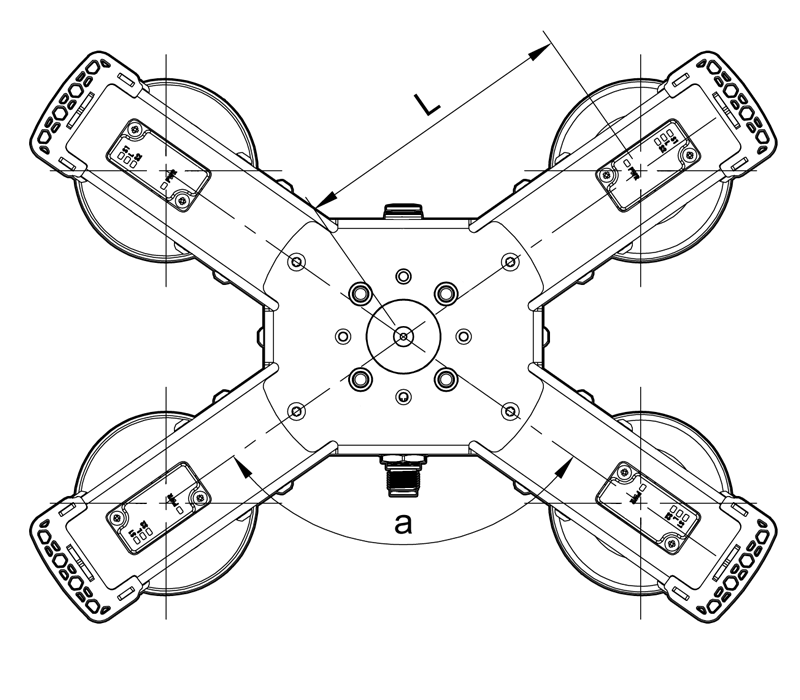

DIMENSIONS ˄

SUCTION CUP PLACEMENT

Horizontal distance to edge

Vertical distance to edge

ACCESSOIRES ˅

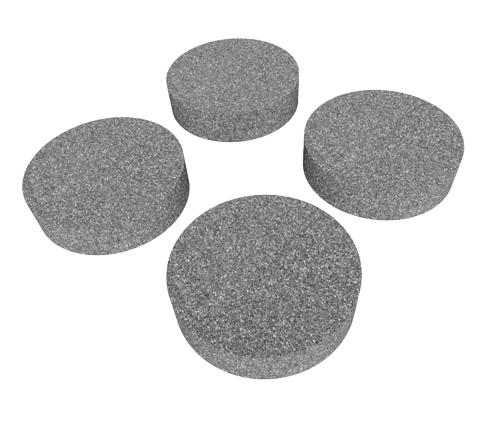

Filter set

Contains 4 replacement filters.

Product nr.: 100000x

- PU foam

- Cleanable

Price: RFQ

Quantity:

Suction cup set

Product nr.: 100000x

Contains 4 Piab 0205162 suction cups.

- Diameter 75 mm

- Dual hardness

Price: RFQ

Quantity:

ENQUIRY ˅

| Description | Quantity | Price | Total |

|---|

Total price: €0,-

* The prices shown here are indicative and may differ from the prices in the final quotation.

✓ Succesfully added to enquiry.

We respect your privacy, and only use functional cookies to improve our service.

We respect your privacy, and only use functional cookies to improve our service.

x

x

FEATURES

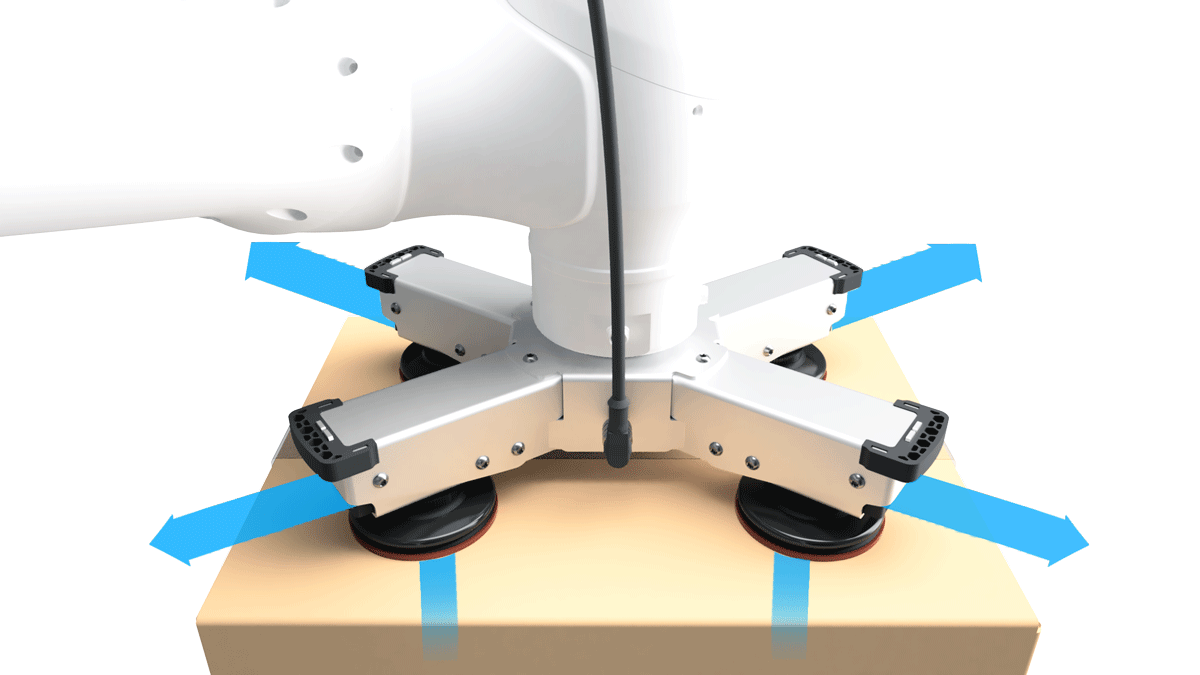

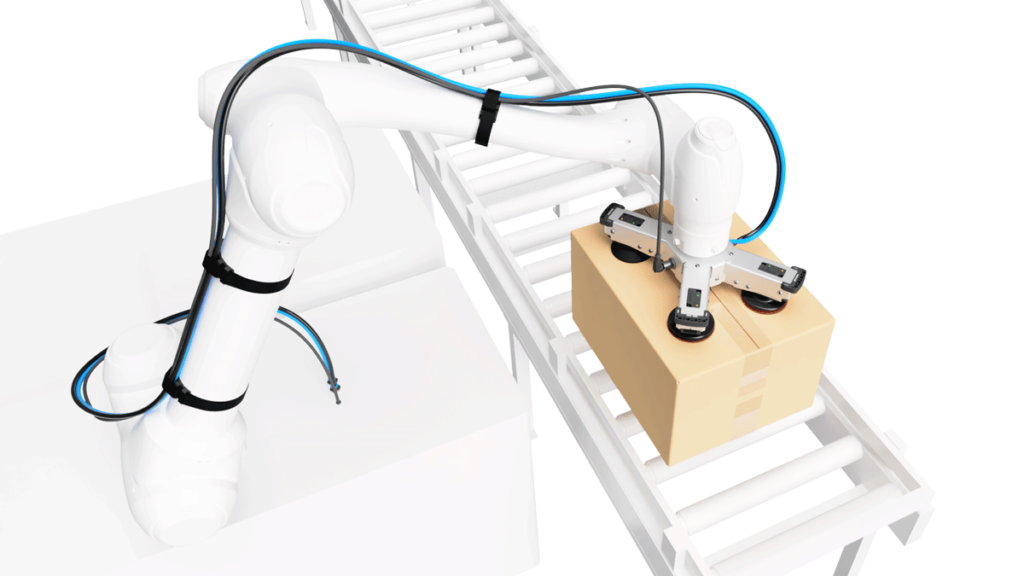

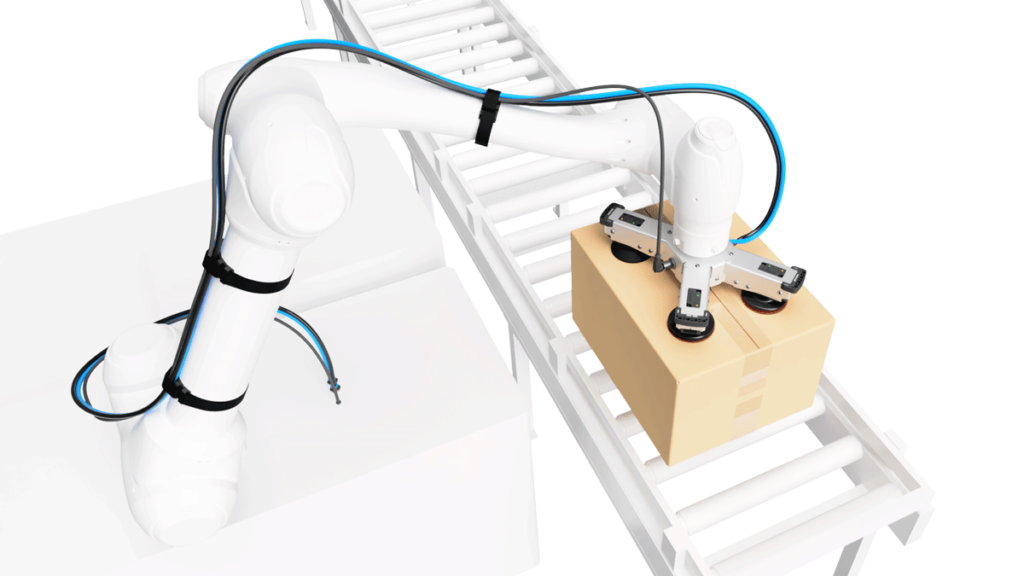

High lifting capacity

Toolit grippers feature a sturdy aluminium frame, creating a lightweight yet strong construction that supports lifting objects up to 35 kg. This high lifting capacity makes the tool suitable for even the most demanding cobot applications.

Smart

V-series tools can be configured to have vacuum switches that monitor the vacuum in each suction cup. By measuring the level of vacuum, the air consumption of the tool can be optimized.

Powerful

The V-series are equipped with four high-flow vacuum ejectors which are placed directly above the suction cups. This allows the tools to lift even the most porous cardboard boxes.

Safe

The configurability of the Toolit concept allows the suction cups to be placed close to the corner of the box, where it is the strongest. This improves lifting stability and prevents tearing or buckling. Additionally, the tool contains two pneumatic channels that can be fed individually, and soft rubber tool tips to comply with safety standards for collaborative robots such as ISO/TS 15066.

Easy to integrate

All tools are designed to mate with an ISO 9409-1-50-4-M6 flange as used by most collaborative robot manufacturers. Adapter plates for robots and cobots with a different flange design are available upon request.

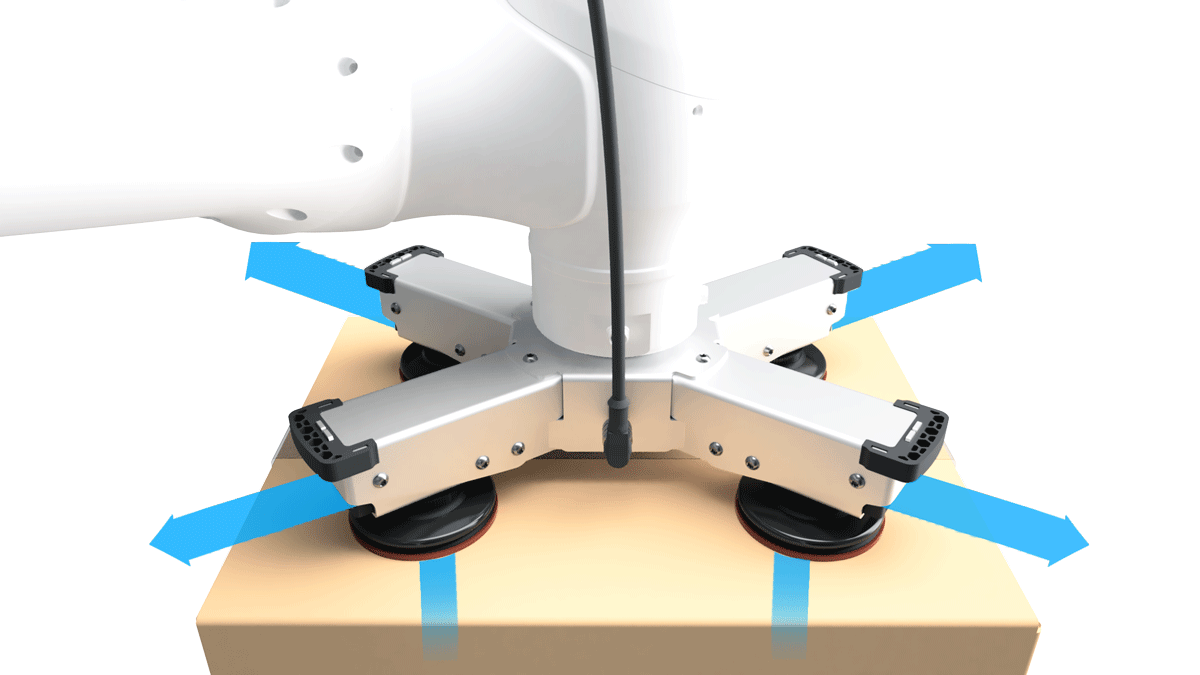

Configurable & customizable

For larger orders we offer the possibility to configure the geometry of the tools by adjusting the length and angle of the arms. We can furthermore customize the appearance of the tool by anodizing various parts of the tool’s frame to match your company colours or laser engrave your logo onto the tools.

FEATURES

High lifting capacity

Toolit grippers feature a sturdy aluminium frame, creating a lightweight yet strong construction that supports lifting objects up to 35 kg. This high lifting capacity makes the tool suitable for even the most demanding cobot applications.

Smart

V-series tools can be configured to have vacuum switches that monitor the vacuum in each suction cup. By measuring the level of vacuum, the air consumption of the tool can be optimized.

Powerful

The V-series are equipped with four high-flow vacuum ejectors which are placed directly above the suction cups. This allows the tools to lift even the most porous cardboard boxes.

Safe

The configurability of the Toolit concept allows the suction cups to be placed close to the corner of the box, where it is the strongest. This improves lifting stability and prevents tearing or buckling. Additionally, the tool contains two pneumatic channels that can be fed individually, and soft rubber tool tips to comply with safety standards for collaborative robots such as ISO/TS 15066.

Easy to integrate

All tools are designed to mate with an ISO 9409-1-50-4-M6 flange as used by most collaborative robot manufacturers. Adapter plates for robots and cobots with a different flange design are available upon request.

Configurable & customizable

For larger orders we offer the possibility to configure the geometry of the tools by adjusting the length and angle of the arms. We can furthermore customize the appearance of the tool by anodizing various parts of the tool’s frame to match your company colours or laser engrave your logo onto the tools.

ABOUT

The Toolit platform is designed to help companies find a solution for their lifting problem. Our smart configurator helps you select the right product in seconds, instead of browsing the internet for hours to find a suitable solution. The platform is aimed at tooling for cobots but our goal is to eventually provide a standardized solution for all lifting problems.

Feel free to contact us with any questions you might have. If you cannot find a standard solution that works for you, we can assist in developing a customized tool for your application, or help you integrate our tools in your production line.

Wadcon, is specialized in designing, producing and installing machines for lifting, hoisting and material handling. Since 1989 the machines of Wadcon have been used throughout Europe leading to a wealth of experience in the fields of hydraulics, pneumatics, electronics, control technology and mechatronics.

Gripper & Handeling Solutions has over 50 years of experience in vacuum technology, gripper technology, and product handling. With our personal approach, Gripper & Handelng Solutions responds to the market’s need for support and technical assistance in these areas. This applies to replacements and new constructions, as well as improvement projects. In addition to a wide range of components for building grippers using vacuum, pneumatic, or electromechanical technology, G&H Solutions specializes in supplying complete grippers tailored to customer specifications.